W-15 & Fuel Stop Inline Fuel Filter

|

Fuel flow is up to 150 litres per hour together with a water separation efficiency greater than 98% and a pressure drop of only 20 mbar offering minimal restriction to fuel flow. Either transparent or metal bowl options are available and all models are fitted with a washable stainless steel element which means no replacement elements. Installation is before the fuel lift pump ensuring full system protection with two port sizes available, ½'' x 20 UNF/SAE & M14 x 1.5.

|

View the embedded image gallery online at:

https://www.wasp-pfs.com/products/fuel-filters/w-15-fuel-stop#sigProIdd1e6fdf7b3 |

- Aluminium die-cast filter head/ bracket for easy installation.

- Transparent (Trogamid® T5000) or aluminium bowl options.

- Pleated stainless steel washable element, surface area 50 cm2.

- Thumb screw plug to drain water and impurities from bowl.

- Ball valve to drain water and impurities from bowl (optional on transparent bowl models only).

-

The WASP W-15 series has three stages of operation

1. Separation:

The incoming flow of fuel oil changes velocity and direction, reducing the possibility of further reduction of any water droplets present through impact.2. Coalescence:

This takes place on and just below the flow dispersion member allowing the separated water to descend to the bottom of the filter bowl.3. Filtration:

The fuel finally passes through the stainless steel filter element. This removes all particulate above 100 micron still suspended in the fuel after the separation process.

| W-15 range | Filtration (micron) | Details |

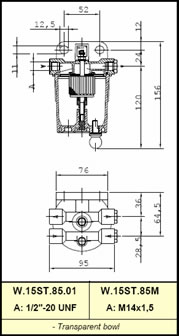

| W-15ST.85.01 | 100mic stainless steel | 1/2" x 20 UNF ports, clear bowl, drain plug |

| W-15ST.85M | 100mic stainless steel | M14x1.5 ports, clear bowl, drain plug |

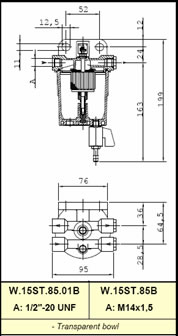

| W-15ST.85.01B | 100mic stainless steel | 1/2" x 20 UNF ports, clear bowl, drain tap |

| W-15ST.85B | 100mic stainless steel | M14x1.5 ports, clear bowl, drain tap |

| W-15ST.85Mpps | 15mic paper | M14x1.5 ports, clear bowl, drain plug |

| W-15ST.85pps | 15mic paper extended length | M14x1.5 ports, clear bowl, drain plug |

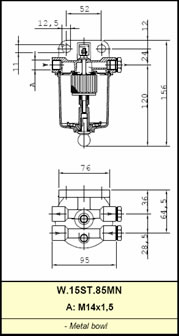

| W-15ST.85MN | 100mic stainless steel | M14x1.5 ports, metal bowl, drain plug |

| W-15FS | Fuel stop | Stops fuel flow if water level is too high |

| Add-on /spare | Details |

| W60450/0015P | Standard replacement 15 mic paper element (all inc 85Mpps, except 85pp) |

| W60200/0015P | Replacement extended paper element (15 micron) for 85pps model only |

| W60450/01 | Replacement 100 mic stainless steel element |

| W014.0800.004 | Replacement seal kit |

| W-15FS | Unique fuel-stop filter |

W-15 FS Unique fuel-stop filter

When water level reaches the pre-determined level, the flow of fuel is halted. This offers a safe way to ensure water in fuel contamination doesn’t reach your engine.

The internal precision machined float ensures only fuel passes; it is free to move within the filter and as the water is separated, will float on that water content collecting in the bowl.

The W-15FS range does not offer particulate filtration, hence there not being a micron rating next to the unit's details above, however engine protection from water content is unparalleled in such a compact form.

For more technical information, please see the Technical Details tab.

| Maximum flow rate | 2.5 Lts/min (150 L/Hr) |

| Connections | 1/2''-20 UNF or M14x1,5 |

| Pressure tested to | 2 bar |

| Environment temperature range | -20°+120 °C |

| Filtering Degree | 100 micron |

Installation

- If necessary refit the two port plugs supplied with the filter. If they are not to be repositioned check they are correctly tightened.

- Follow the flow direction according to the arrows on each of the four ports.

- This range of filters should be installed on the suction side of the fuel supply system before the lift pump.

Maintenance

- Check regularly for separated water

- Drain off any separated water or impurities regularly via the thumb screw drain plug or valve

- Remove, clean and re-fit the stainless steel element as necessary

- replace paper element when required, see product range tab

Fuel Filters Fuel Polishing Gallery Fuel Contaminations Fuel Additives