WB-40 Classic Fuel Cleaning System

40 litres per minute fuel polishing system, cleaning fuel to 10 micron, removing both free water, bacteria and particulate.

Fuel infection from water or other foreign matter can damage or destroy an engine, so maintaining fuel quality is vital.

The WB range of Fuel Cleaning Systems offer a fuel cleaning solution with many of the features of the W-PFS range but is the more cost effective solution. These quality systems will clean your fuel automatically, removing water, bacterial infection, sludge solid and semi-solid contaminates from your fuel up to 10 micron. The WB Classic range can be custom built to your specifications and we have a wide range of add-on options to meet all your needs.

Available in either 220v 50hz 1ph AC, 24v DC or 12v DC

If you require touch screen technology, BMS and field bus functionality, emulsified water removal and filtering to 2 micron, we recommend the W-PFS Range.

SUITABLE FOR

SUITABLE FOR

Tank sizes 25,000 to 50,000 litres Cleaning 40 litres per minute

PLC CONTROL

PLC CONTROL

Manual and auto set up options. AC and DC power options.

CLEAN TO 10 MICRON

CLEAN TO 10 MICRON

including free water, bacteria, dirt and particulate.

-

Mobile fuel polishing

Mobile fuel polishing

Mobile fuel polishing

Mobile fuel polishing

-

Bacteria Conditioner Included

Bacteria Conditioner Included

Bacteria Conditioner Included

Bacteria Conditioner Included

-

40 lit/min wall mounted

40 lit/min wall mounted

40 lit/min wall mounted

40 lit/min wall mounted

-

Best quality fittings

Best quality fittings

Best quality fittings

Best quality fittings

-

Add-on: Drip tray

Add-on: Drip tray

Add-on: Drip tray

Add-on: Drip tray

-

Protection

Protection

Protection

Protection

-

Fuel Polishing results

Fuel Polishing results

Fuel Polishing results

Fuel Polishing results

-

Fuel Tank Contamination

Fuel Tank Contamination

Fuel Tank Contamination

Fuel Tank Contamination

-

Easy to use controls

Easy to use controls

Easy to use controls

Easy to use controls

-

WB-40 Wall Mounted

WB-40 Wall Mounted

WB-40 Wall Mounted

WB-40 Wall Mounted

https://www.wasp-pfs.com/products/fuel-polishing-systems/wb-range/wb-40#sigProId229cfc0e27

- Free water, dirt, particulate and bacteria removal to 10 micron

- Advanced fuel filter/water separation technology

- 5 stage centrifugal filtration process (see more)

- 40 litres per minute flow rate

- ideal for 25,000 - 50,000 litre fuel tanks

- 220v 50hz 1ph AC or 24v DC

- 1 x BMS Output 2 x BMS Inputs

- Mounting options include wall mounting, mild steel enclosure or portable trolley

- Automatic shutdown when servicing is required

- Manual and Automatic modes

- Simple remote monitoring

- Add-on options available

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

|

|||

|

Wall Mounted Models |

Mild Steel Enclosure Models |

Portable Models |

|||

|

WB-40 40 lit/min Power Options |

24v DC, |

24v DC, |

24v DC, |

Need help selecting the right system for your requirements? Use our new Product Selector.

For more technical information, please see the Technical Details tab.

|

We offer a range of customisation options including:

|

View the embedded image gallery online at:

https://www.wasp-pfs.com/products/fuel-polishing-systems/wb-range/wb-40#sigProId4e32e4b695 |

| Model |

WB-40 |

| Max flow rate |

40 lit/min max flow rate** |

|

Recommended Tank size |

25,000 - 50,000 |

| Power options |

220v 50hz 1ph AC 24v DC

|

| Finish options |

Wall Mounted, Frame Mounted, Enclosure, Trolley |

| Particulate removal to |

10 Micron |

| Control unit |

PLC |

| BMS Outputs |

1 |

| BMS Inputs |

2 |

| Fuse |

220vAC 2.5a 24vDC 11a |

| Typical current |

220vAC 1.5a 24vDC 8a |

| Suction capability |

5m vertical, we always recommend using a non return valve and priming the unit before use. |

| Port sizes |

1"BSP-P male |

| Pump Body |

PTFE Gear |

| Gears |

PTFE Vane |

| Shaft |

Stainless steel |

| Seal |

Flouoroelastomer lip seal |

|

Dimensions * |

600x900x350mm |

| Weight * |

26kg approx (AC) 29kg approx (DC)

|

*Please note, the dimensions, weights above are for the wall mounted version. The enclosure revision will be slightly larger and heavier.

**Flow rates quoted assume the ideal conditions, a large positive head, no left, wide pipe work, etc. Narrow pipes, tight bends, elbows, lifts and other such external factors can and will impact on the maximum flow achieved by the system.

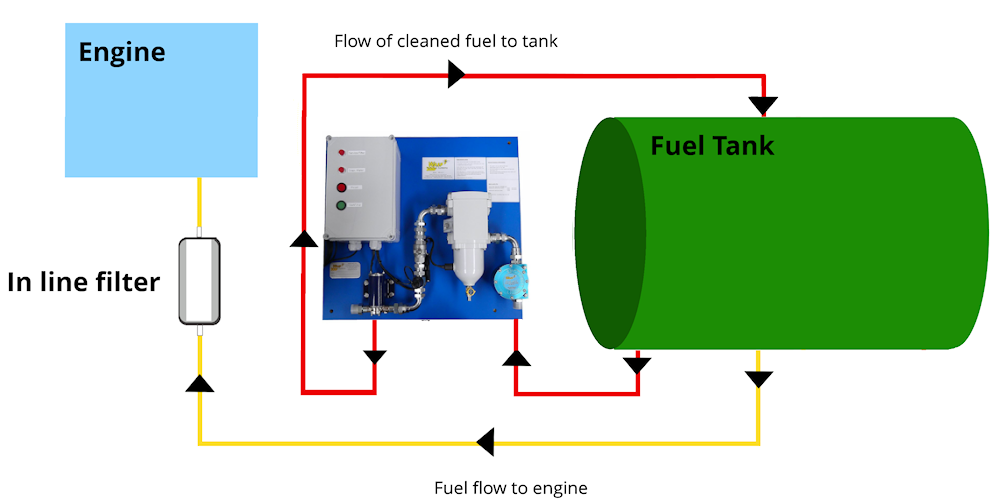

The WB range of products is typically wall mountable and should be installed close to the fuel tank it is cleaning.

In any typical fuel tank, the pipe feeding fuel to the engine is not at the bottom, however to successfully clean fuel, the pickup pipe going to the WB unit should be right at the bottom of the tank, below the engine feed.

The return pipe from the WB unit should ideally be at the top of the tank at the opposite end to the pick up; if this is not possible the top of the tank at the same end is acceptable.

Apart from that, the list below highlights our recommendations.

- A fused spur is required to power the system (24v DC or 220v 50hz 1ph AC).

- Only two pipes are required (input/pickup and output/return)

- We recommend a non return valve on the input pipe

- Alternatively we recommend a foot valve at the tank end of the input pipe

- We recommend isolating ball valves before and after the system.

See the product support page for more information.

Try our helpful new PRODUCT SELECTOR to select the model for your needs.