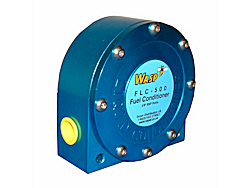

Magnetic Fuel Conditioners

Stored fuel degrades over time and becomes contaminated by condensation, leading to bacteria and fungus. The fuel is then out of spec and causes power failure and damage to engine parts. The usual port of call for a fuel bacterial infection would be to use a biocide. While biocides are effective in bacterial treatment and prevention, the environmetal impact and possible damage to seals are a real concern. The WASP Fuel Conditioner neutralises bacterial content before an infection can develop.

|

View the embedded image gallery online at:

https://www.wasp-pfs.com/products/other-fuel/fuel-conditioning-units#sigProId73e66eb57b |

- Breaks down bacteria particles

- Prevents bacteria infection taking hold

- Environmentally friendly

- Avoids requirement for chemical biocides

- Saves money on replacement elements for fuel / water filter

- Independant study proves effectiveness

The WASP Fuel Magnetic Conditioner works by neutralising bacterial content before a bacterial infection can take hold aswell as aiding the effective removal of sludge and other biomass by your existing fuel filter/water separator. As well as helping the environment, the Fuel Magnetic Conditioner can save you money as filter elements are not required to be replaced as frequently.

For more information on the independant study please contact us.

|

|

|

|

|

| Model | W-FLC-500 | W-FLC-1000 | W-FLC-1500 | W-FLC-2500 |

| Ports | 3/8" BSP | 1/2" BSP | 3/4" BSP | 1" BSP |

| Fuel flow (gravity fed) | 500 lit/hr | 1000 lit/hr | 1500 lit/hr | 2500 lit/hr |

|

|

|||

| Model | W-FLC-3000 | W-FLC-4000 | ||

| Ports | 1" BSP | 2" BSP | ||

| Fuel flow (gravity fed) | 4000 lit/hr | 15,000 lit/hr | ||

| This email address is being protected from spambots. You need JavaScript enabled to view it. | This email address is being protected from spambots. You need JavaScript enabled to view it. | |||

|

|

|

|

|

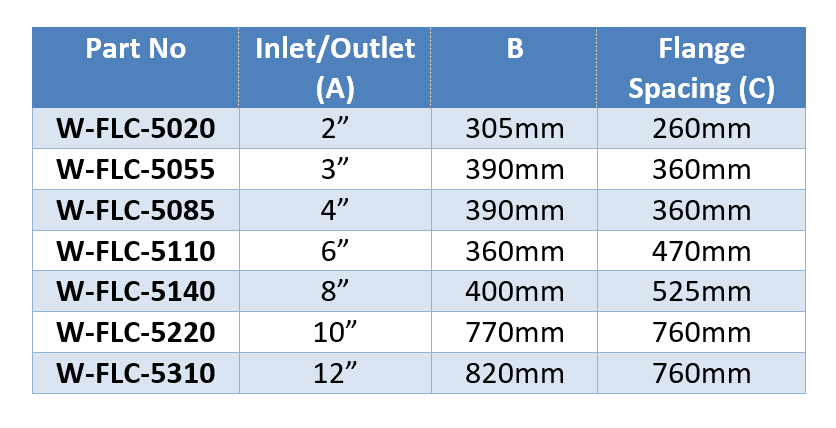

| Model | W-FLC-5020 | W-FLC-5055 | W-FLC-5085 | W-FLC-5110 |

| Ports | 2" BSP | 3" BSP | 4" BSP | 6" BSP |

| Fuel flow (gravity fed) | 20,000 lit/hr | 55,000 lit/hr | 85,000 lit/hr | 110,000 lit/hr |

|

|

|

||

| Model | W-FLC-5140 | W-FLC-5220 | W-FLC-5310 | |

| Ports | 8" BSP | 10" BSP | 12" BSP | |

| Flow rate (Gravity fed) | 140,000 lit/hr | 220,000 lit/hr | 310,000 lit/hr |

For more technical information, please see the Technical Details tab.

| Model | W-FLC-500 | W-FLC-1000 | W-FLC-1500 | W-FLC-2500 |

| Ports | 3/8" BSP | 1/2" BSP | 3/4" BSP | 1" BSP |

| Power required | none | none | none | none |

| Dimensions | 102x102x42mm | 127x134x58mm | 127x134x58mm | 175x170x77mm |

| Weight (approx.) | 900g | 1.2kg | 1.2kg | 4.5kg |

| Fuel flow (gravity fed) | 500 lit/hr | 1000 lit/hr | 1500 lit/hr | 2500 lit/hr |

| Material | Marine Grade corrosion resistant 6061 Aluminium | |||

| Seals | Hydrogenated Nitrile butadiene Rubber (HNBR) | |||

| Case | Anodising Light Blue with two mounting holes at the bottom corners | |||

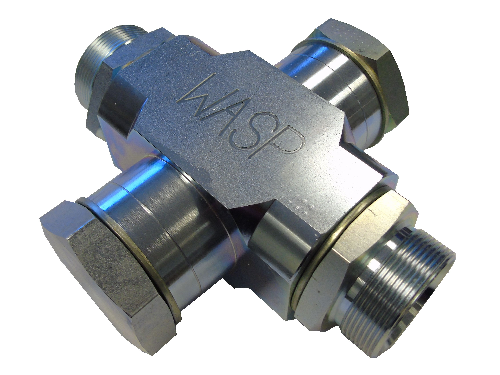

| Model | W-FLC-3000 | W-FLC-4000 |

| Ports | 1" BSP | 2" BSP |

| Power required | none | none |

| Dimensions | 200x110x254 | |

| Fuel flow (gravity fed) | 4000 lit/hr | 15,000lit/hr |

| Seals |

HNBR |

|

| Case | 304 Stainless Steel |

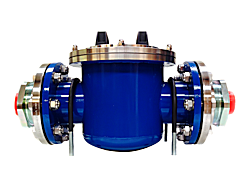

| Model | W-FLC-5020 | W-FLC-5055 | W-FLC-5085 |

| Ports | 2" BSP | 3" BSP | 4" BSP |

| Power required | none | none | none |

| Dimensions | 170x260x280mm | 220x360x335mm | 220x360x335mm |

| Fuel flow (gravity fed) | 20,000 lit/hr | 55,000 lit/hr | 85,000 lit/hr |

| Seals |

Viton |

||

| Case | 304 grade stainless steel, powder coated, internally bead blasted | ||

| Model | W-FLC-5110 | W-FLC-5140 | W-FLC-5220 | W-FLC-5310 |

| Ports | 6" BSP | 8" BSP | 10" BSP | 12" BSP |

| Power required | none | none | none | none |

| Dimensions |

325x470x420mm |

325x525x460mm | 406x760x600mm | 406x760x675mm |

| Fuel flow (gravity fed) | 110,000 lit/hr | 140,000 lit/hr | 220,000 lit/hr | 310,000 lit/hr |

| Seals | Viton | |||

| Case |

304 grade stainless steel, powder coated, internally bead blasted |

|||

W-FLC-500,1000,1500 & 2500

The W-FLC should be installed in the fuel line before the main filter/water separator as in the example below. By installing in this way, the unit is able to literally condition the fuel in advance of its cleaning process. The effect of the W-FLC is to neutralise the live bacterial content of the fuel – stopping it from multiplying, and to increase the effectiveness of the water separator allowing it to trap more of the biomass; thus protecting the serviceable parts of the filter, and mean fewer replacement filter elements are needed.

The W-FLC should be installed in the fuel line before the main filter/water separator as in the example below. By installing in this way, the unit is able to literally condition the fuel in advance of its cleaning process. The effect of the W-FLC is to neutralise the live bacterial content of the fuel – stopping it from multiplying, and to increase the effectiveness of the water separator allowing it to trap more of the biomass; thus protecting the serviceable parts of the filter, and mean fewer replacement filter elements are needed.

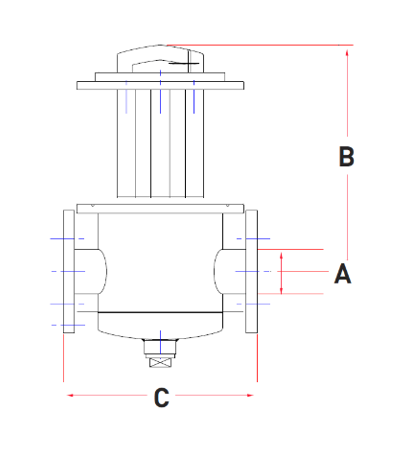

W-FLC-5000 Range

The WASP W-FLC-5000 range is typically installed on the feed line from the day or bulk tank, just before the primary fuel filter.

On larger systems, other W-FLC-5000 units may be installed elsewhere to give extra protection for day tanks or other fuel related products.

Please also ensure that the W-FLC-5000 is installed in a position which gives adequate access above to lift out the magnets during servicing and maintenance. Also access is required to the underneath of the unit to connect a hose or hold a bucket during draining.

- Identify a suitable location

- Ensure enough clearance to carry out cleaning as the rods must be lifted out of the unit to clean. See dimensions in column B in the table below.

- Mark and then cut out the correct length of pipe section to be removed to accommodate the unit and isolation valves. Ensure the cut is level and burr free. (Isolation valves are not included with the W-FLC-5000)

- Install appropriate isolation valves to the pipework and fit the valves to the two PN16 flanges (see below for flange dimensions) or threaded fittings as appropriate.

- Position the unit in place then align and secure the fittings to connect the unit to the valves.

- Open the isolation valves and prime the fuel system

- Run the fuel system at normal operating temperature and check installation integrity.

W-PFS Fuel Cleaning Range Gallery Download Brochure Download W-FLC 5000 product brochure