FAQ's about Fuel Cleaning

Fuel Polishing FAQs

FUEL POLISHING FAQs

We firstly recommend you read our "Guide to Fuel Polishing"

- get an insight in to what fuel polishing is

- know about fuel contaminations and their effects

- see how our units work

To select which unit suits your requirements, we recommend using our new Product Selector Widget. Alternatively, you can contact us so our fuel cleaning experts can advise you.

The quickest and easiest way of finding out what is buy using our new Product Selector Widget. The system you need will vary based on the following factors: What makes WASP PFS Ltd unique is our skill and ability to design and build our own systems. This gives us the flexibility and expertise to design and manufacture products specific to your budget, requirements and specifications. View some examples of bespoke systems

. Our standard system begins at 8 lit/min 24v DC powered, and ranges up to 400 lit/min 220v 50hz 1ph AC powered. We custom build as well, with our largest unit currently being able to handle up to 1600 lit/min (that's nearly 100,000 litres per hour). Systems typically have manual, automatic (programmable timer) and BMS (Building Management System) control as standard. They are self pumping and self monitoring fuel cleaning devices which are typically installed near to your fuel tanks. We also offer portable systems, units in IP rated enclosures, and frame mounted units and field bus communication options. For more advice on selecting the unit to suit your requirements, please contact us. We have customers all over the world, including Europe, Saudi Arabia and Iceland and likewise we have a large world-wide distributor network. For more information on our distributor network, please go to our International section

. We have detailed instructions on the ideal positioning of the units to achieve optimum performance, here is some basic information on the W-PFS and WB Range installation.

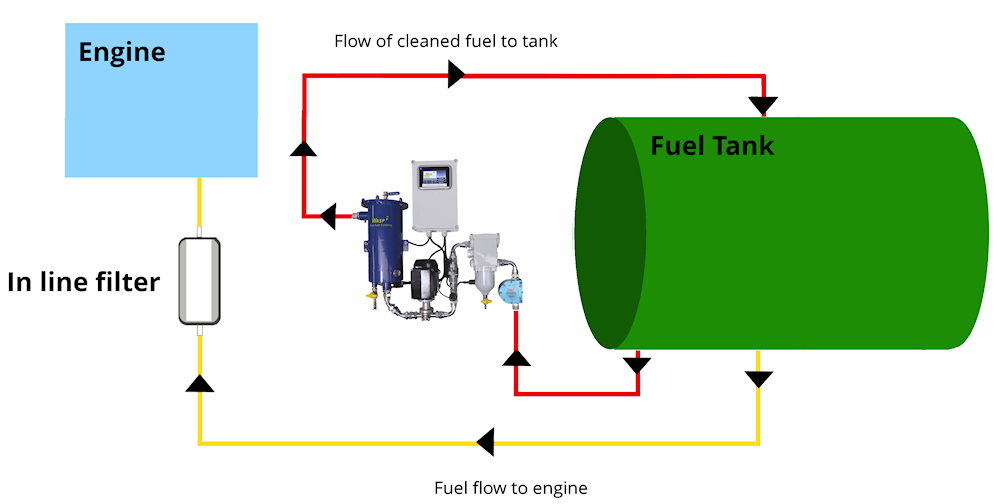

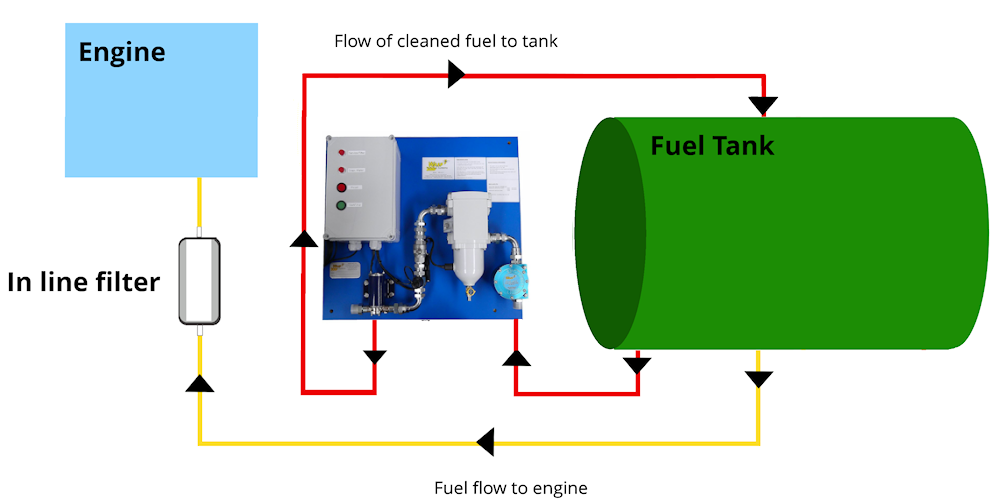

Ensure the system is securely fastened to a wall or other suitable solid structure. The unit should have unique pipe work from any existing fuel driven equipment. The input to the WASP system should feed from the bottom of the fuel tank (via a ball valve and a foot valve or non return valve) The system should pick-up fuel from the lowest point of the tank at one end, (below the level of the fuel feed to your engine) and ideally return it to the highest point at the opposite end. In any typical fuel tank, the pipe feeding fuel to the engine is not at the bottom, however to successfully clean fuel, the pickup pipe going to the WB unit should be right at the bottom of the tank, below the engine feed. The WB range of products is typically wall mountable and should be installed close to the fuel tank it is cleaning. In any typical fuel tank, the pipe feeding fuel to the engine is not at the bottom, however to successfully clean fuel, the pickup pipe going to the WB unit should be right at the bottom of the tank, below the engine feed. The return pipe from the WB unit should ideally be at the top of the tank at the opposite end to the pick up; if this is not possible the top of the tank at the same end is acceptable. Apart from that, the list below highlights our recommendations. We will work with you to customise the appropriate W-PFS unit to suit your specific requirements.

There is a range of Add-ons

to our standard W-PFS range which include, heaters, fans, trolley fittings, stair climbing units, custom size units, dosing systems and many more.

To see examples of some recent custom made units, have a look at our Bespoke Systems

page.

Feature

W-PFS Range

WB Range

Final Clean to

2 Micron

10 Micron

Flow rate (litres per minute)

8-400

10-40

Touch screen

BMS (Building Management System) Option

Field Bus Option

Customise to your requirements

Multiple tank option

Tank sizes (litres)

7500 - 1,000,000

10,000-50,000

Support available

Training available

Remove Free Water

Remove emulsified water

Remove bacterial matter

Auto Drain Option